Sectors

Industries We Serve

Prashant Machine Tools supports customers throughout the process, helping them achieve their objectives crankshaft- camshaft and bearing manufacturing and heavy engineering industries. Our expertise and comprehensive solutions ensure optimal performance and productivity for our clients.

01

Bearing Industries

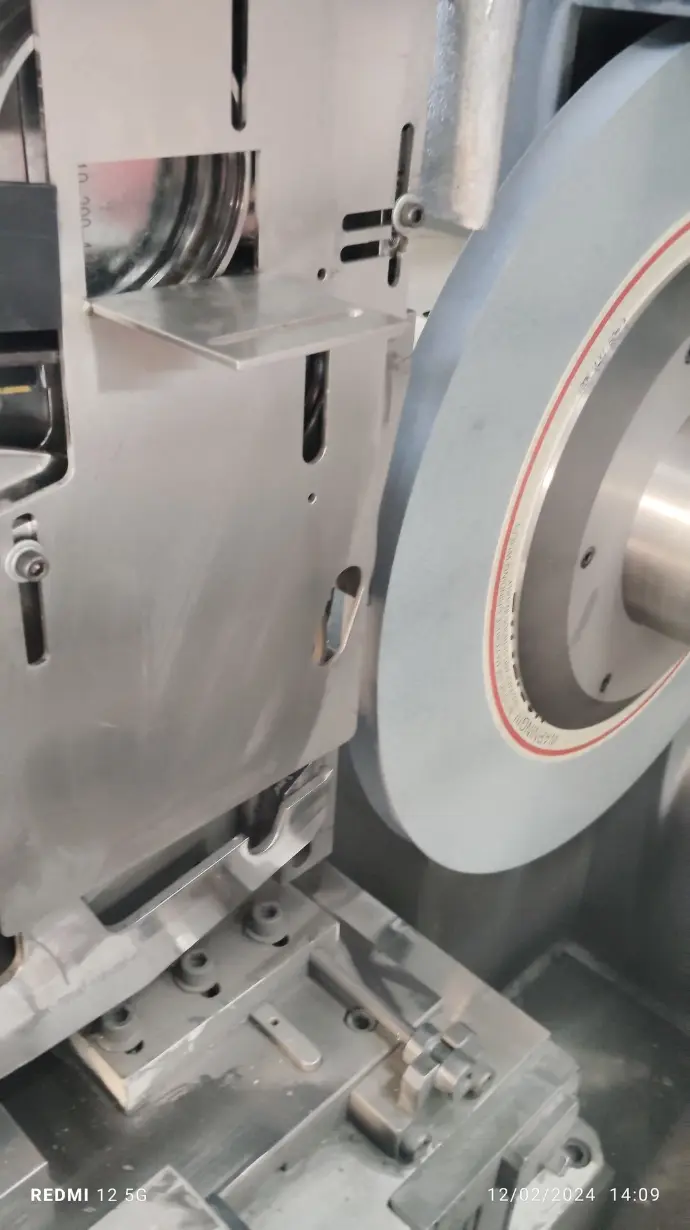

Specializes in grinding and reconditioning solutions for the bearing industry, including ID, OD, face, bore, flange, and roller grinding solutions. Our services ensure precision, efficiency, and extended machinery performance, trusted by industry leaders.

02

Camshaft industries

Offers advanced grinding and reconditioning services for the camshaft industry. With a focus on precision and efficiency, we ensure superior quality and performance in every aspect of camshaft manufacturing and maintenance.

03

Crankshaft industries

Specializes in crankshaft pin and journal grinding solutions. Our advanced machines ensure high precision, flawless surface finish, and exceptional efficiency, delivering optimal performance for crankshaft manufacturing and reconditioning needs.

04

Precision industries

Provides precision grinding and reconditioning solutions tailored for the precision industries. Our advanced machinery ensures unparalleled accuracy, efficiency, and quality to meet the exacting standards of precision manufacturing.

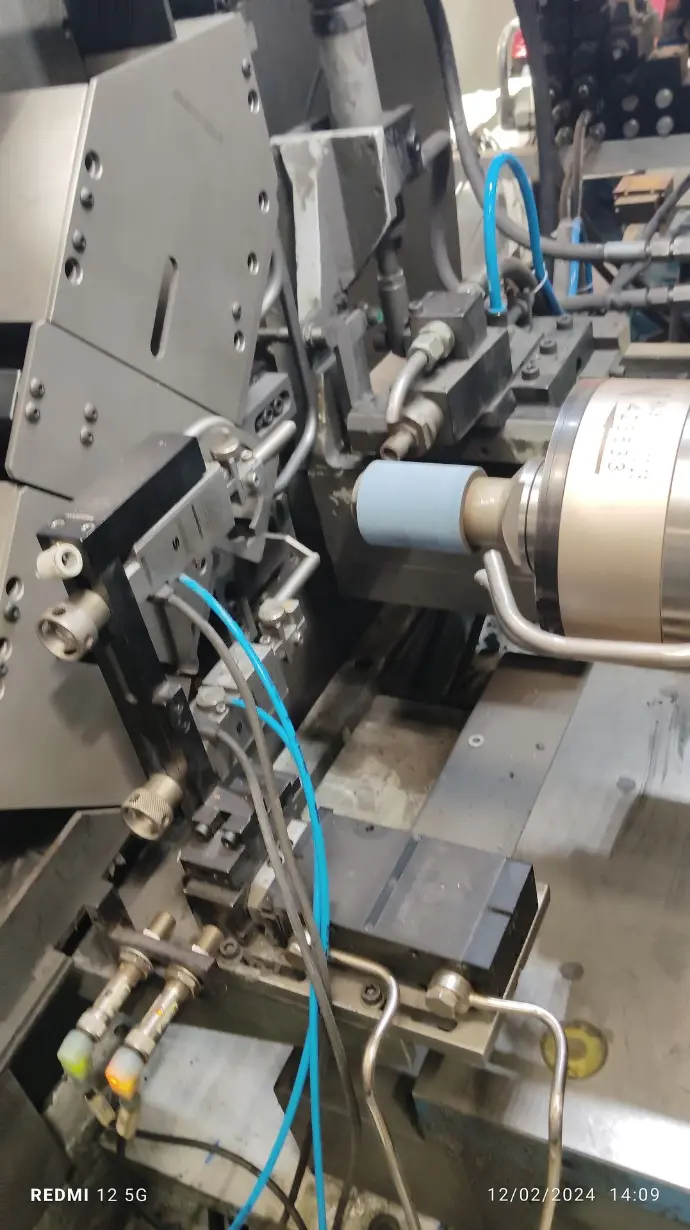

For over 14 years, PMT has been RECONDITIONING AND TRANSFORMING conventional machines into advanced CNC systems, particularly in areas such as bearing face IDD grinding and crankshaft grinding for the automotive industry. Our expertise lies in high-precision machinery.

|

Feature |

Conventional Machine |

Upgraded CNC Machine |

|

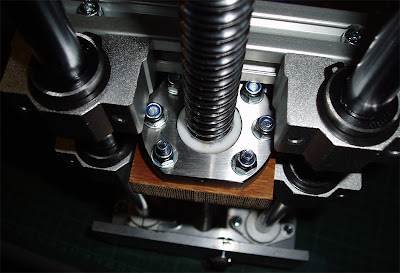

Axis Movement |

Hydraulic cylinder |

N/O guides & high precision ball screw driven by servo motor |

|

Accuracy & Repeatability |

Limited by hydraulic system |

High precision due to ball screws and servo motors |

|

Speed |

Slower due to hydraulic response time |

Faster and more consistent speeds with servo motors |

|

Stiffness |

Lower stiffness due to hydraulic compliance |

Higher stiffness for improved machining performance |

|

Work Head |

Rotating magnet type |

Fixed magnet type (improved stability) |

|

Wheel Head Oscillation |

Cam driven (limited control) |

High precision ball screw and servo motor for precise control |

|

Work Head Drive |

Induction motor |

Variable speed through servo motor for optimal control |

|

In-process Gauging |

Optional |

Can be integrated for real-time quality control |

|

Spindle Motor |

Standard motor |

High frequency (HF) spindle with variable speed for diverse materials |

|

Wheel Dressing |

Hydraulic dresser (limited capabilities) |

2-axis CNC dresser for precise and efficient dressing |

|

Wheel Balancing |

Manual |

Dynamic system for improved surface finish and tool life |

Machines we Recondition

Crankshaft Journal Grinding CNC machine

Centerless Roller Grinding Machine

Crankshaft Pin Grinding CNC machine

OD grinding machines